RESEARCH FACILITIES ON THE LBC

With the support of the Free State of Bavaria, the chairs of various universities, together with industrial partners, are setting up large research facilities and laboratories which can be used across a range of disciplines. These facilities are available for research, teaching and training.

Advanced ALM Lab

Advanced ALM Lab

Highly-complex structures from the 3D printer: Innovative products are researched and developed in the Advanced ALM Lab, ranging from extremely heat-resistant components for rocket propulsion, to new types of component for commercial aircraft, right through to... motorbikes! The picture shows the “Light Rider” from Airbus APWorks, a lightweight 35 kg prototype for the electric motorcycle, made from bionically-optimised metal components, all of which were developed and produced on the LBC.

System Lab

System Lab

A ground-breaker for integrated infrastructure: The System Lab accelerates research with regard to system design, simulation and integration, and the system testing of new technologies in the field of manned and unmanned fixed wing and rotary wing aircraft. Here shown the System Lab for “DeckFinder”, developed by Airbus Defence and Space, in which autonomous landing approaches onto a moving ship’s deck are optimised and further developed.

Algae tech facility

Algae tech facility

A greenhouse of innovation: The TUM, together with its project partner Airbus, has built a 1,500 m algae technology centre for research within the context of the “Algae Powered Flight“ project. For the first time, feasibility studies for algal processes linked to various climate zones, algae strains and cultivation technologies can be held in this special building. Alongside renewable fuel, the focus is also on bio-based production of lightweight construction materials.

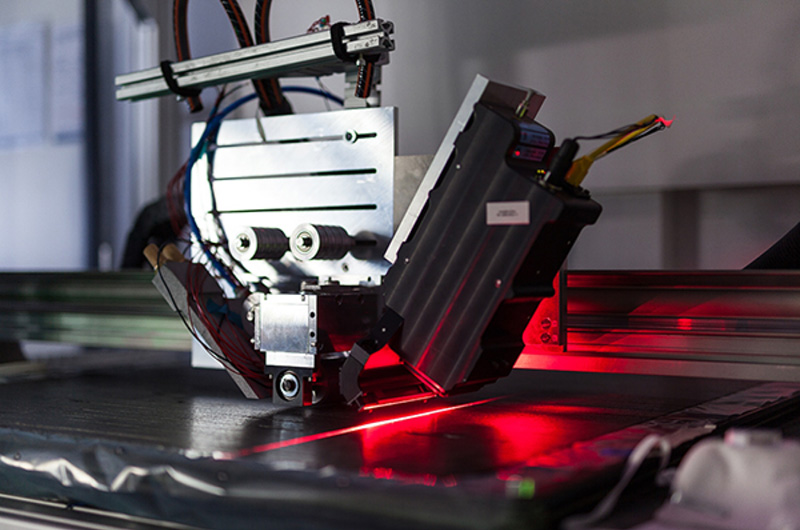

Processing Lab 4.0

Processing Lab 4.0

Where the future takes shape: The Processing Lab 4.0 project will further extend the processing lab for the Carbon Composites chair at TUM that already exists on the LBC. Among other features, a key contribution to this will be made by cutting-edge 3D printers for new materials and composites, and a continuous fabrication unit.

Power Lab

Power Lab

Less aircraft noise and less pollution in the air: On the Power Lab test bench, researchers and engineers test lightweight and reliable engines, networks, energy storage systems and control systems for energy management in aeroplanes and helicopters. The Power Lab is the nucleus of the centre of expertise for hybrid and all-electric aircraft engines on the LBC.